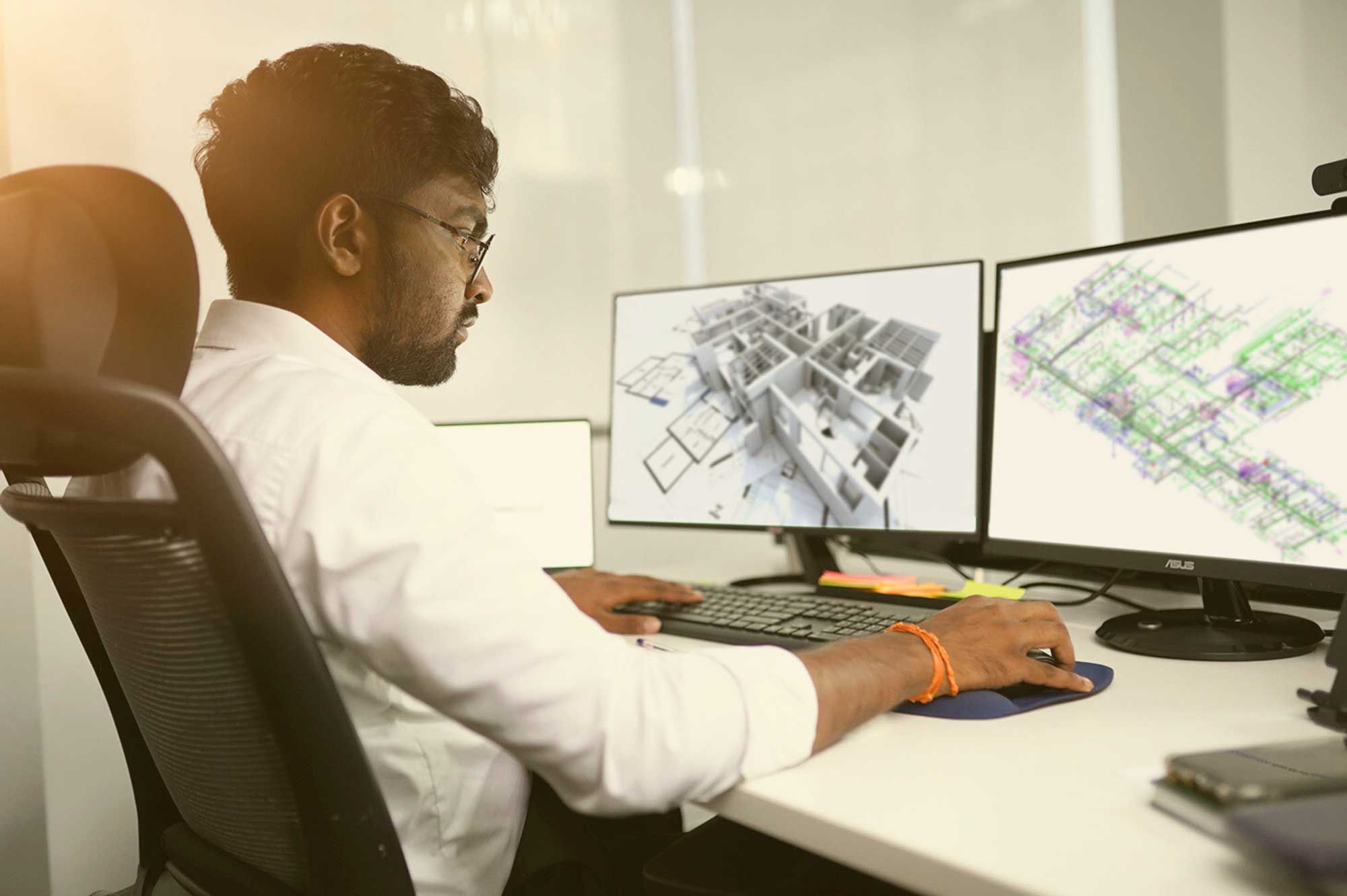

Whether it's a commercial skyscraper, a residential complex, or an industrial facility, MEP components ensure functionality, safety, and efficiency. However, to integrate these complex systems seamlessly, MEP drawings play a critical role.

MEP drawings are detailed technical diagrams that illustrate the design, placement, and installation of mechanical, electrical, and plumbing systems in a building. They serve as a roadmap for engineers, architects, and contractors, ensuring a coordinated approach to construction. Without accurate MEP drawings, costly errors, delays, and inefficiencies can arise, leading to budget overruns and compromised structural integrity.

In this guide, we’ll explore everything you need to know about MEP drawings—from their definition and types to their preparation process and significance in construction. Whether you're a construction professional, an MEP mechanical engineer, or someone looking for expert MEP engineering services, this comprehensive breakdown will give you valuable insights into why MEP drawings are indispensable.

What Are MEP Drawings?

MEP drawings are a set of detailed blueprints that provide a visual representation of the mechanical, electrical, and plumbing systems within a building. These drawings are essential for ensuring that all MEP components are properly designed, coordinated, and installed without conflicts.

Each category of MEP drawings serves a unique purpose:

-

Mechanical Drawings – Cover heating, ventilation, and air conditioning (HVAC) systems, including ductwork, airflow, and thermal efficiency considerations.

-

Electrical Drawings – Illustrate the wiring, lighting, power distribution, and circuit layouts required for a building’s electrical system.

-

Plumbing Drawings – Depict water supply lines, drainage systems, sanitary piping, and fixtures, ensuring proper flow and waste management.

These drawings help engineers and contractors visualise the integration of MEP systems within the overall structure, minimising clashes between components and ensuring compliance with industry standards and local regulations. With technological advancements, MEP drawings are now created using Building Information Modelling (BIM) software, enhancing accuracy and collaboration.

By using MEP drawings, construction teams can optimise design efficiency, reduce costs, and prevent potential on-site issues, making them an invaluable tool in any construction project.

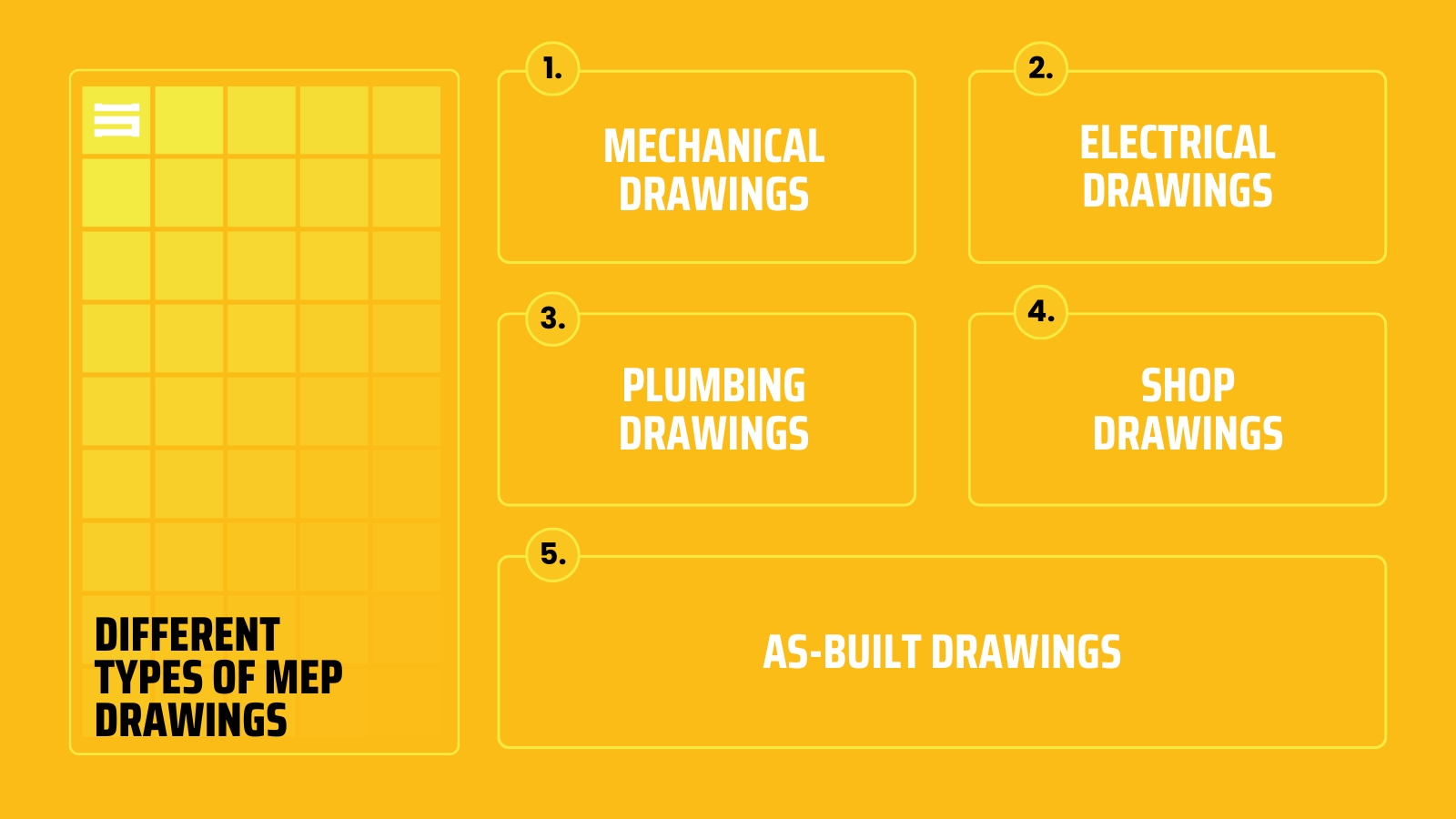

Different Types of MEP Drawings

MEP drawings are categorised into various types, each serving a crucial role in the construction process. Let’s take a detailed look at the key types:

1. Mechanical Drawings

Mechanical drawings focus on the design, installation, and integration of heating, ventilation, and air conditioning (HVAC) systems. These systems are vital for maintaining air quality, temperature regulation, and energy efficiency in buildings.

Key Types of Mechanical Drawings:

-

HVAC Layout Drawings: These drawings illustrate the placement of HVAC units, air ducts, vents, diffusers, and exhaust systems. They ensure proper airflow distribution and thermal comfort throughout the building.

-

Ductwork Drawings: These highlight the size, material, and routing of air ducts. Properly designed ductwork is essential to minimise energy loss and ensure optimal system performance.

-

Equipment Details Drawings: These provide specifications and placement details for HVAC components such as chillers, boilers, air handling units (AHUs), and cooling towers. Proper equipment positioning improves energy efficiency and accessibility for maintenance.

Mechanical drawings must comply with local building codes and energy efficiency standards to ensure safety, sustainability, and compliance with environmental regulations.

2. Electrical Drawings

Electrical drawings map out the power supply and distribution system of a building. These drawings are crucial for ensuring safety, preventing power overloads, and optimising energy usage.

Key Types of Electrical Drawings:

-

Lighting Layout Drawings: These show the placement of lighting fixtures, switches, dimmers, and emergency lighting systems. They ensure proper illumination levels and enhance the building's aesthetics and functionality.

-

Power Distribution Drawings: These depict the electrical wiring, circuit breakers, distribution boards, and main power supply points. Properly designed power distribution drawings ensure balanced loads and prevent electrical hazards.

-

Fire Alarm & Security System Drawings: These illustrate the layout of fire alarm systems, smoke detectors, CCTV cameras, motion sensors, and access control systems. Safety and security system drawings are essential for ensuring compliance with fire safety regulations and emergency preparedness.

Electrical drawings play a vital role in energy management, load balancing, and electrical safety, making them indispensable for any construction project.

3. Plumbing Drawings

Plumbing drawings outline the design and layout of water supply, drainage, and gas systems. Properly designed plumbing systems ensure efficient water flow, prevent leaks, and support sanitation standards.

Key Types of Plumbing Drawings:

-

Water Supply Drawings: These indicate the routing of fresh water throughout the building, including pipe materials, fixture locations, and pressure control mechanisms.

-

Drainage and Waste System Drawings: These drawings depict wastewater and sewage management, including the placement of traps, vents, and sewer lines to prevent blockages and contamination.

-

Gas Piping Drawings: These outline the layout of gas supply systems, including safety shut-off valves and pressure regulation points, ensuring safe operation.

Plumbing drawings help construction teams avoid cross-contamination, reduce water wastage, and ensure compliance with plumbing codes.

4. Shop Drawings

Shop drawings are detailed, and precise technical drawings used by contractors and fabricators to manufacture and install MEP components. These drawings serve as a bridge between design intent and on-site execution.

Key Types of Shop Drawings:

-

Fabrication Drawings: These provide detailed manufacturing instructions for ductwork, pipes, cable trays, and other prefabricated MEP components. Fabrication drawings help manufacturers ensure accurate production and quality control.

-

Installation Drawings: These serve as step-by-step guides for on-site assembly and installation of mechanical, electrical, and plumbing systems. These drawings are critical for ensuring components fit together correctly and adhere to safety standards.

Shop drawings help contractors minimise errors, reduce material wastage, and optimise installation efficiency.

5. As-Built Drawings

As-built drawings are created after the construction phase is completed. They reflect any modifications made during installation and provide an accurate record of the final MEP system layout.

Importance of As-Built Drawings:

-

Future Maintenance & Repairs: These drawings help facility managers locate critical MEP components for maintenance, repairs, and upgrades.

-

Legal & Compliance Documentation: Many jurisdictions require as-built drawings to confirm that the installed MEP systems comply with building codes and safety regulations.

-

Renovations & Retrofits: Having accurate as-built drawings simplifies the process of modifying or expanding a building’s infrastructure.

As-built drawings act as essential references for long-term facility management and compliance with construction regulations.

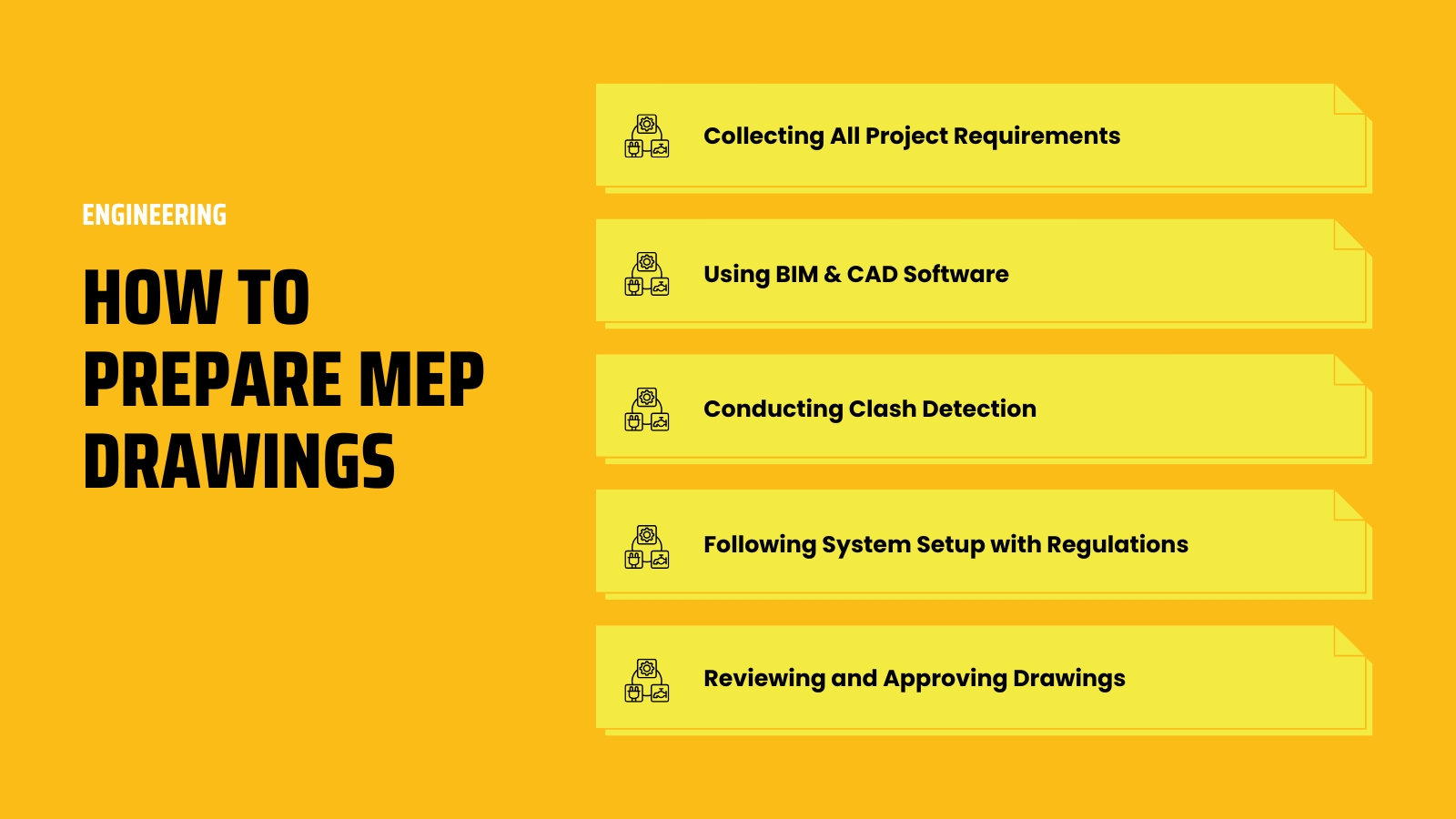

How to Prepare MEP Drawings

Preparing accurate MEP drawings requires a structured approach. Here’s how it’s done:

1. Collecting All Project Requirements

Before drafting begins, engineers must gather information such as building dimensions, architectural plans, and regulatory standards. Understanding project scope is crucial for creating compliant MEP designs.

2. Using BIM & CAD Software

Modern MEP drawings are created using advanced software like AutoCAD and Revit. BIM technology enables real-time collaboration, reducing design conflicts and improving accuracy.

3. Conducting Clash Detection

Clash detection is performed to identify potential interferences between mechanical, electrical, and plumbing systems. This process ensures smooth integration without structural modifications during installation.

4. Following System Setup with Regulations

MEP drawings must adhere to local construction codes and safety standards. Engineers incorporate these guidelines into their designs to avoid legal issues and ensure system efficiency.

5. Reviewing and Approving Drawings

Once drafted, MEP drawings undergo multiple reviews by engineers, consultants, and project stakeholders before final approval and execution on-site.

By following these steps, MEP drawings enhance construction efficiency, reduce costs, and prevent rework.

Importance of MEP Drawings in Construction Projects

MEP drawings are essential for construction projects due to the following reasons:

1. Enhancing Coordination

Construction projects involve multiple teams working simultaneously on different aspects of a building. The integration of mechanical, electrical, and plumbing systems within a unified design ensures that all components fit together without interference.

MEP drawings provide a visual representation of how HVAC systems, electrical wiring, and plumbing networks will be installed within the structure. This prevents potential clashes, such as:

-

Electrical conduits interfering with HVAC ductwork

-

Plumbing pipes obstructing structural elements

-

Improper placement of mechanical equipment affecting accessibility

By using clash detection software like BIM (Building Information Modelling), engineers can identify and resolve conflicts before construction begins. This improves workflow coordination, reducing unnecessary modifications and ensuring a seamless execution of all MEP systems.

2. Improving Cost and Time Savings

Accurate MEP drawings help minimise construction errors, which in turn leads to significant cost and time savings. Errors in MEP installations can be expensive to rectify once construction is underway, often requiring additional materials, labour, and time.

By ensuring that all design specifications, material requirements, and installation procedures are clearly outlined before work begins, MEP drawings prevent:

-

Rework and delays caused by incorrect placements

-

Material wastage due to miscalculations

-

Additional labour costs from unexpected modifications

Additionally, prefabrication of MEP components based on detailed shop drawings can help reduce on-site construction time, improving overall project efficiency.

3. Prioritising Safety and Compliance

Safety is a top priority in construction, and MEP drawings play a key role in ensuring that mechanical, electrical, and plumbing systems meet safety standards.

Regulatory bodies impose strict guidelines on fire safety, electrical wiring, water distribution, and ventilation to protect building occupants. Non-compliance with these standards can lead to:

-

Legal penalties and fines

-

Delays in project approval

-

Hazardous working conditions

MEP drawings ensure that installations comply with:

-

Fire safety codes (e.g., proper fire suppression systems, emergency exits, and smoke ventilation)

-

Electrical standards (e.g., circuit load balancing, earthing, and voltage regulations)

-

Plumbing and sanitation regulations (e.g., proper drainage, pipe sizing, and contamination prevention)

By adhering to these codes, MEP engineering consultants help mitigate risks, ensure regulatory approval, and enhance the overall safety of a building.

General FAQ Section

Who Creates MEP Drawings?

MEP drawings are typically created by MEP engineering consultants, who specialise in designing mechanical, electrical, and plumbing systems. These professionals use CAD and BIM software to develop detailed plans that meet construction requirements.

How Long Do MEP Drawings Take?

The time required to create MEP drawings depends on project complexity. A standard commercial building may take 2-6 weeks, while larger industrial projects require more time for coordination and approvals.

Are MEP Drawings Necessary for Small-Scale Projects?

Yes, even small projects benefit from MEP drawings, ensuring efficient installation and preventing costly design mistakes.

Conclusion

MEP drawings are a fundamental part of modern construction, providing a clear blueprint for mechanical, electrical, and plumbing systems. From HVAC layouts to power distribution and plumbing schematics, these drawings streamline project execution, reduce errors, and ensure compliance with safety regulations.

As technology advances, BIM and 3D modelling continue to enhance the accuracy of MEP drawings, improving coordination between engineers, architects, and contractors. Whether you're planning a small-scale development or a large commercial project, investing in high-quality MEP drawings is crucial for long-term efficiency and cost savings.

For expert MEP engineering services, working with experienced MEP engineering consultants ensures that your project is executed with precision and compliance.

About us

At Stonehaven, we specialise in providing top-tier MEP engineering services across the UAE. Our team of MEP engineering consultants delivers mechanical and electrical drawings, plumbing drawings, shop drawings, and MEP contract services for a wide range of construction projects.

With years of industry expertise, we offer comprehensive MEP design, estimation, and supervision, ensuring your project meets the highest standards of safety, efficiency, and sustainability. Whether you need HVAC layouts, electrical wiring diagrams, or plumbing system designs, our expert team ensures seamless integration and execution.