Safety is at the heart of every successful civil engineering and construction project. Whether constructing skyscrapers, bridges, or retaining walls, ensuring structural integrity and preventing failure is paramount. This is where the Factor of Safety (FoS) plays a critical role. The concept goes beyond a simple calculation – it is a benchmark that influences design decisions, material choices, and overall project reliability.

In the fast-paced world of Engineering Procurement Construction (EPC) services, understanding safety factors has become even more essential. Projects led by EPC contractors rely on precise FoS calculations to ensure systems and structures are not just efficient but exceptionally safe.

This blog will dive deep into the Factor of Safety in civil engineering, exploring formulas, contributing factors, and challenges, while emphasising why safety is critical for construction sites. Whether you’re an engineer, site manager, or EPC professional, you’ll walk away with insights to improve reliability and enhance safety measures in your projects.

What is the Factor of Safety (FoS) in Civil Engineering?

The Factor of Safety, commonly abbreviated as FoS, is a measure used to determine how much stronger a structure or component is compared to the required load or stress it is expected to endure. In simpler terms, it acts as a buffer between expected performance and potential failure.

FoS is often expressed as a ratio, comparing the maximum strength of a material or system to the actual load it will experience. For example, if a beam can support 10,000 kg but is only subjected to 5,000 kg, the Factor of Safety is 2.

In civil engineering, FoS plays a pivotal role in maintaining structural integrity and ensuring safety across projects like buildings, roads, dams, and retaining walls. It accounts for uncertainties such as material variability, external forces, and human error. A higher safety factor reduces the likelihood of catastrophic failure, but it must be balanced to avoid excessive material costs.

For industries like EPC construction where accuracy and reliability are non-negotiable, FoS ensures every project meets safety standards.

What is the Formula of Factor of Safety?

Understanding the Factor of Safety starts with knowing its formula. The basic equation for FoS is:

Key Components in the Formula

-

Ultimate Load Strength: This refers to the maximum load a material or structure can withstand before failure.

-

Allowable Stress Load: This is the stress a structure is designed to carry safely under normal conditions.

These formulas are foundational in civil engineering calculations, ensuring designs are robust and reliable while meeting regulatory standards.

What is the Safety Factor For, Especially in Engineering Projects?

The Factor of Safety serves multiple purposes in civil engineering and construction projects:

-

Mitigating Uncertainty: Material properties, environmental factors, and construction methods can vary. FoS ensures a safety buffer for unforeseen circumstances.

-

Preventing Structural Failure: Even minor errors in design or calculations can lead to catastrophic failures. FoS provides a margin of safety to safeguard lives and property.

-

Enhancing Reliability: By incorporating FoS, engineers ensure that structures perform reliably under extreme conditions, such as earthquakes, heavy wind loads, or high traffic.

-

Versatile Standards: Industry regulations require certain FoS values for different types of projects. For example, buildings may have a minimum FoS of 1.5, while bridges may require 2.0 or higher.

-

Supporting EPC Projects: EPC contractors depend on accurate FoS calculations to guarantee safety across all stages of Engineering Procurement Construction. FoS helps optimise material use while maintaining project integrity.

Ultimately, the safety factor ensures that civil engineering projects achieve the delicate balance between economy, efficiency, and protection.

Which Factors Contribute to Safety on Construction Projects?

Ensuring safety on construction projects is not just about theoretical calculations; it requires a holistic approach that combines robust design, quality materials, skilled personnel, and efficient management. Below are the key factors that contribute to maintaining safety on construction sites.

1. Material Quality

The quality and strength of construction materials play a significant role in ensuring safety. Materials like steel, concrete, timber, and composites must meet specific strength and durability requirements to withstand loads and environmental pressures. Substandard or poorly sourced materials can compromise the Factor of Safety (FoS), leading to structural failures or project delays. Regular testing of material samples and sourcing from certified suppliers are critical steps in maintaining quality control. For instance, high-grade concrete with consistent curing ensures reliability in foundation work, while reinforced steel must be free of defects to withstand tension forces.

2. Design Considerations

Design is the backbone of any construction project, and errors at this stage can have catastrophic consequences. Proper load calculations, stress analysis, and structural modelling ensure that designs are both safe and functional. Design teams must also factor in extreme conditions like high wind loads, earthquakes, and temperature fluctuations to avoid potential risks during the operational phase of the project.

3. Workforce Training

A construction project is only as strong as its workforce. Proper training equips workers with the knowledge and skills to perform their tasks safely and efficiently. This includes understanding site safety protocols, using tools and machinery correctly, and handling materials responsibly. Regular training programmes, workshops, and safety drills help workers stay prepared for emergencies while minimising human error. Skilled workers are also more adept at identifying and reporting hazards early, which can prevent accidents.

4. Environmental Conditions

External factors like weather, soil composition, and seismic activity significantly influence structural performance. Engineers must account for environmental uncertainties when designing and executing projects. For example, in regions prone to earthquakes, structures must include reinforced foundations and damping systems to enhance stability. Similarly, weak or expansive soils require additional ground treatment to ensure load-bearing capacity. Ignoring these variables can compromise the safety margin and lead to unexpected failures.

5. Safety Equipment and Protocols

Implementing comprehensive safety measures ensures the physical safety of workers and protects the integrity of the project. Key elements include:

-

Personal Protective Equipment (PPE): Helmets, gloves, safety harnesses, and reflective vests reduce injury risks.

-

Site Inspections and Audits: Regular inspections help identify safety gaps, ensuring that protocols are continuously updated.

-

Emergency Response Plans: Clear evacuation plans and first-aid stations prepare workers for unforeseen incidents.

By combining these tools and protocols, site managers can create a secure working environment that minimises accidents and aligns with industry regulations.

6. EPC Project Management

For EPC contractors managing complex Engineering Procurement Construction (EPC) projects, effective project management is vital to ensuring safety. EPC projects involve multiple phases – design, procurement, and execution – and any lapse in coordination can lead to safety risks. Strong project management practices ensure seamless communication between engineers, procurement specialists, and on-site teams. This reduces the likelihood of errors, delays, and resource misallocation. EPC companies that prioritise safety integrate advanced monitoring systems, risk assessments, and regular progress reviews to align every phase with FoS principles.

Benefits of Factor of Safety (FoS) in Civil Engineering

The Factor of Safety (FoS) is more than just a mathematical concept in civil engineering; it is a foundational principle that underpins the safety, reliability, and success of construction projects. By incorporating an appropriate FoS into designs and calculations, engineers can ensure that structures not only meet but exceed the minimum requirements for performance and safety. Here are the key benefits of implementing FoS in civil engineering:

1. Preventing Structural Failures

At its core, the FoS acts as a crucial safety net that significantly reduces the risk of structural collapses. These failures can be caused by unforeseen loads, such as extreme weather conditions, or by human errors in construction and material handling. By designing structures with a FoS, engineers create a buffer that accommodates unexpected stresses and strains. This safeguard is essential for protecting lives, as well as the substantial financial investments involved in construction projects. In regions prone to natural disasters, a higher FoS can make the difference between a structure that withstands an earthquake and one that does not.

2. Improving Reliability and Durability

A well-calculated FoS ensures that structures are not only safe but also reliable and durable over their intended lifespan. By considering factors such as material fatigue, environmental degradation, and repeated load cycles, engineers can design structures that maintain their integrity for decades. Reliability engineering and system safety principles are integrated into every aspect of the design process, from selecting materials to determining load paths. This comprehensive approach reduces the likelihood of unexpected maintenance costs and extends the useful life of the infrastructure, providing long-term value to owners and users alike.

3. Cost Optimisation

While it might seem that a higher FoS would increase costs due to the need for more robust materials or additional construction processes, it contributes to cost optimisation in the long run. An optimised FoS strikes a balance between safety and cost-efficiency. By precisely calculating the necessary safety margins, engineers avoid over-engineering structures, which can lead to unnecessary expenses. EPC (Engineering, Procurement, and Construction) companies in the UAE, for example, often adopt advanced modelling tools and simulation software to determine the optimal FoS. This approach minimises material waste, reduces construction time, and lowers overall project costs without compromising safety.

4. Compliance with Regulations

Adhering to safety standards and building codes is mandatory in the civil engineering industry. Incorporating appropriate FoS values ensures that projects meet all legal and regulatory requirements effortlessly. Regulations often specify minimum FoS values for different types of structures and materials to protect public safety. By aligning designs with these standards from the outset, engineers facilitate smoother approval processes and reduce the risk of costly revisions or delays. Compliance also demonstrates a company's commitment to industry best practices and ethical responsibility.

5. Building Trust and Reputation

For engineering firms and construction companies like Stonehaven, delivering safe, high-quality structures is essential for building trust with clients and stakeholders. A strong reputation for safety and reliability can set a company apart in a competitive market. By consistently implementing appropriate FoS in projects, companies showcase their dedication to quality engineering and client satisfaction. This commitment not only enhances relationships with existing clients but also attracts new business opportunities, as reputation is a significant factor in the selection of contractors and consultants in the industry.

6. Addressing Uncertainties

Construction projects are often subject to various uncertainties, such as variable soil conditions, unexpected loading scenarios, and environmental changes. The FoS accommodates these uncertainties by providing a margin of safety that accounts for potential deviations from the expected conditions. For instance, soil properties can vary significantly even within a single site, affecting the foundation's performance. By incorporating a suitable FoS, engineers can design foundations that remain stable despite these variations. Similarly, the FoS helps structures withstand unexpected loads, such as those from future expansions or changes in use, ensuring long-term adaptability and resilience.

Challenges in FoS in Civil Engineering

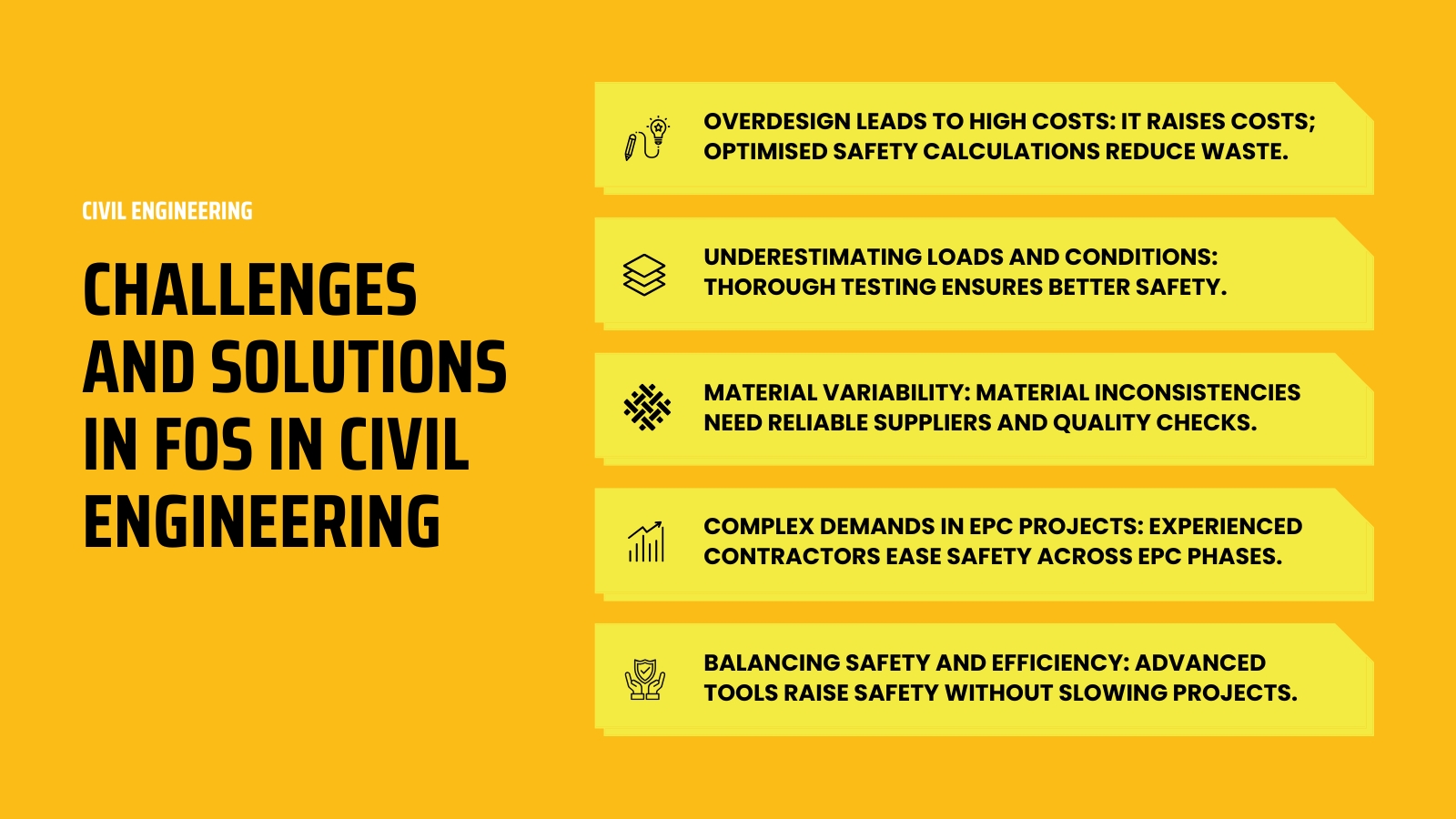

While the Factor of Safety (FoS) is an essential component in engineering design and construction, its implementation poses several challenges that engineers must navigate to ensure both safety and efficiency. Below is a detailed exploration of these challenges and their corresponding solutions:

1. Overdesign Leading to High Costs

Excessively conservative safety factors can result in overdesign, which leads to the use of more materials than necessary, thereby driving up project costs. This not only impacts the project's budget but may also reduce its overall sustainability by increasing resource consumption.

Solution: Engineers can mitigate this issue by using optimised FoS calculations tailored to specific project needs. Advanced software tools and simulation programmes can help determine precise FoS values that strike a balance between safety and cost-efficiency.

2. Underestimating Loads and Conditions

Inadequate consideration of potential loads, such as those caused by wind, seismic activity, or unexpected operational stresses, can lead to underestimated safety margins. This oversight increases the risk of structural failures and compromises the integrity of the project.

Solution: Adopting thorough risk analysis methods, including scenario planning and stress-testing, can address this challenge. Incorporating site-specific environmental data ensures that all relevant loads and conditions are accurately accounted for during the design process.

3. Material Variability

Natural variations in material properties, such as tensile strength, ductility, or fatigue resistance, can significantly impact the reliability of the applied FoS. Using materials with inconsistent properties may lead to unforeseen vulnerabilities in the structure.

Solution: To counter material variability, sourcing materials from reliable suppliers with a proven track record is essential. Additionally, conducting regular quality control tests and audits throughout the project ensures that materials meet the required standards and specifications.

4. Complex Demands in EPC Projects

Engineering, Procurement, and Construction (EPC) projects often involve multiple teams working across various phases, making it challenging to maintain consistent safety standards. Miscommunication or misalignment between teams can create gaps in safety management.

Solution: Partnering with experienced EPC contractors, such as Stonehaven, who specialise in seamless project management and safety integration, can simplify these complexities. A well-coordinated EPC contractor ensures that safety protocols are consistently applied from engineering design to execution.

5. Balancing Safety and Efficiency

Engineers frequently face the challenge of balancing rigorous safety requirements with the need for project efficiency. Excessive emphasis on safety can slow down project timelines, while prioritising efficiency might lead to safety compromises.

Solution: Utilising advanced modelling and simulation software allows engineers to identify an optimal FoS that maximises safety without hindering efficiency. Such tools enable detailed analyses and predictive modelling to strike the perfect balance.

Conclusion

The Factor of Safety (FoS) is a cornerstone of civil engineering, ensuring the safety, reliability, and efficiency of construction projects. From towering bridges to retaining walls, FoS calculations provide a crucial buffer against failure while addressing uncertainties in design, materials, and environmental factors.

For companies engaged in EPC construction projects, understanding and implementing FoS is non-negotiable. It ensures compliance, durability, and trust in engineering outcomes. By addressing challenges like cost efficiency and material variability, engineers can optimise safety without compromising project goals.

About us

At Stonehaven, we specialise in delivering Engineering Procurement Construction (EPC) Services that combine safety, quality, and efficiency. As leading EPC contractors in the UAE, our expert teams ensure seamless project execution, from design to delivery.

Our commitment to reliability engineering & system safety means every project we undertake adheres to the highest standards of safety. Whether it’s types of EPC contracts or EPC construction projects, Stonehaven delivers robust solutions tailored to your needs.

Trust Stonehaven to bring your vision to life with precision, reliability, and unparalleled safety.